Flush Mount Maxi Bolt Installation Procedure

Revision 1215

By

Drillco National Group

P. O. Box 2182

Long Island City, NY 11102

Telephone: (800) 391-0052

www.drillcogroup.com

techsupport@drillcogroup.com

1.0 GENERAL REQUIREMENTS

1.1 This procedure specifies drill sizes, minimum hole depths, embedment dimensions, and installation requirements for Maxi-Bolt Coupling anchors as manufactured by Drillco Devices, Ltd. The Coupling anchor offers an internally threaded connection which is slightly recessed below the concrete surface. Allowable-loads for an installation. which utilizes the Maxi-Bolt Coupling Anchor will be based on allowable loads for the Coupling Anchor or for the bolt which is threaded into the Coupling Anchor, depending on which has the lesser material strength.

1.2 Personnel assigned to install Maxi-Bolt anchors should receive training from a Drillco Qualified Instructor before proceeding with work. If the responsible engineer or contractor so desires, personnel will be issued a Qualified Installer's card upon satisfactory completion of such training.

2.0 DRILLING HOLES

2.1 Locating Holes

2.1.1 Mark placement of anchor(s) on concrete.

2.1.2 If required, locate placements of rebar in vicinity of anchor(s) with a rebar locating device and make necessary corrections in location of anchor(s) on concrete.

2.1.3 If location of rebar is not required or if location of anchor(s) has been corrected per 2.1.2, proceed with 2.2.

2.2 Drilling Primary Hole

2.2.1 Holes shall be drilled with a Drillco carbide percussion drill bit, Drillco "Rebar Eater" bit, or Drillco diamond core bit.

2.2.2 Drill bit diameter is specified in Table I .

a. A Drillco DBGNG (drill bit go - no go gauge) shall be used in lieu of the above to determine acceptability of the primary hole bit.

b. This-procedure does not specify a minimum primary hole bit diameter.

2.2.3 Drill hole to depth specified in Table I.

a. Hole depth shall not be less than hole depth specified.

b. Hole may be drilled to any depth greater than hole depth specified.

2.2.4 Holes shall be drilled within 6 degrees of perpendicular to the nominal concrete surface.

a. The use of a guide, level, or square is recommended.

2.2.5 Clean hole of concrete dust and debris.

2.2.6 Measure depth of hole to ensure that minimum hole depth has been achieved.

2.3 Relocating of Hole

2.3.1 If anchor must be relocated and a new hole drilled, the old hole shall be repaired with dry pack grout or in accordance with contract drawings or specifications.

2.4 Drilling Undercut in Primary Hole

2.4.1 Undercut in primary hole shall be drilled only with a Drillco Undercutting Tool.

2.4.2 Cutter diameter B (diameter with cutter(s) in fully opened position) is specified in Table II and illustrated in Figures 1 and 1A.

a. A Drillco UTGNG (undercutting tool go - no go gauge) shall be used in lieu of the above to determine that the cutter blades are within the tolerances specified in Table II.

2.4.3 The depth at which the undercut is formed is controlled by the position of tool's bearing sleeve (C in Figures 1 and 1A). To achieve the correct undercut depth:

a. Set tool's bearing sleeve so that Dimension F in Figure 1 or 1A corresponds to the specified embedment depth of the anchor being installed.

b. When anchors are to be installed prior to placement of attachment, the bottom of the bearing sleeve should be placed in contact with the surface of the concrete.

c. When anchors are being installed through an "in place" attachment, the bearing sleeve should be placed in contact with the surface of the attachment. Furthermore, the attachment should be in contact with the nominal surface of concrete.

2.4.4 With the bearing sleeve in contact with the surface of the concrete or attachment, but with no pressure applied to the drill, start drill motor.

2.4.5 With drill motor running apply a steady pressure on the drill.

2.4.6 When Pin D is in contact with bottom of Slot E (as shown in Figures 1 and 1A) the undercut is complete. To verify this it will be necessary to stop the drill motor and observe the pin location.

2.4.7 After the undercut is complete, stop the drill motor and remove the tool from the hole. Inspect insert blade(s) to ensure that they have not been damaged during the drilling operation.

2.4.8 Clean the hole of concrete dust and debris.

3.0 INSTALLING ANCHORS

3.1 The Drillco Maxi-Bolt is a single wedge type anchor with an expansion sleeve placed between the conical nut and the internally threaded coupling. This expansion sleeve is designed to expand into the undercut created by the Drillco Undercutting Tool as described in 2.4 above.

3.2 Examine Assembled Anchor

3.2.1 Check to ensure that all components are present and that the bolt is correctly assembled. See Figure 2.

3.2.2 No modification to the anchor shall be permitted.

3.3 Setting Anchor

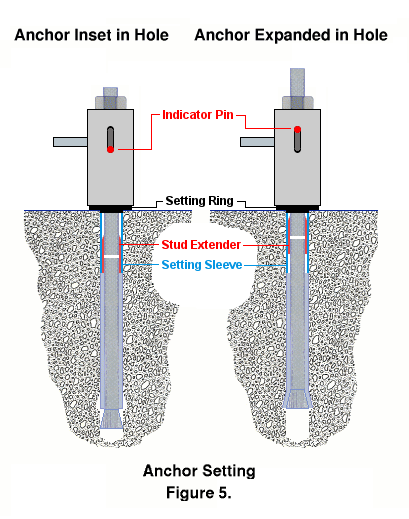

3.3.1 To set the Maxi-Bolt it is necessary to draw the conical nut on the stud bolt up into the anchor's sleeve. In so doing the expansion sleeve will be forced to move laterally into the undercut portion of the hole and the conical nut will seat fully inside the expansion sleeve. See (Figure 5). This process may be accomplished in one of three ways.

3.3.2 Manual Setting

3.3.2.1 Remove internally threaded coupling from anchor and thread stud extender onto the stud end of the anchor. In some cases there is a short length of sleeve above the anchor's plastic washer which must also be removed. Put setting sleeve over the stud extender. Place the end of the stud extender through the center hole of the Bolt Bushing (From Figures 3). The-Bolt Bushing should be oriented so that the 1/16" offset bears against the setting sleeve. Finger tighten a hex nut and washer on anchor bolt assembly.

3.3.2.2 Insert anchor into properly drilled, undercut and cleaned hole with the setting ring between the bottom of the bolt bushing and the concrete surface.

3.3.2.2.1 Because of close tolerance between conical nut O.D. and hole I.D. it may be necessary to lightly hammer the anchor into the hole:

a. If hammering is necessary, steps shall be employed which will prevent damage to the threads of setting rod.

3.3.2.3 Use a wrench to hold the stud extender stationary while the hex nut is tightened. The hex nut should be tightened until the conical nut is seated and the expansion sleeve contacts the I.D. of the conical undercut in the concrete. The installer will note a sudden increase in torque required at this point. During the setting operation, the orientation of the bolt bushing shall be observed. If the bolt bushing rotates more than 180 degrees, use a pipe wrench to prevent further rotation.

3.3.2.4 Loosen hex nut, unscrew stud extender from anchor, and remove setting sleeve from hole. If a short length of sleeve was removed from above the plastic washer, replace it now.

3.3.2.5 Insert internally threaded coupling into hole, chamfered end first, and thread onto anchor.

3.3.3 Setting Anchor with Hand Bolt Setting Tool

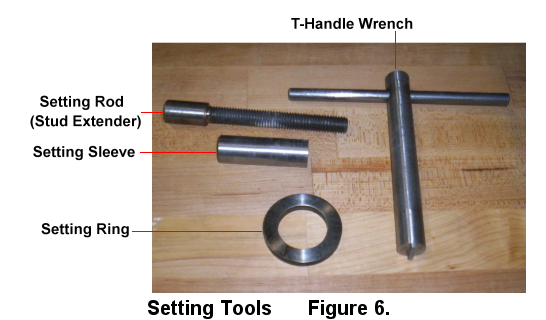

3.3.3.1 Remove internally threaded coupling from anchor and thread stud extender onto the stud end of the anchor. In some cases there is a short length of sleeve above the anchor's plastic washer which must also be removed. Put setting sleeve over the stud extender. Thread stud extender into the bottom of the Hand Bolt Setter so that setting sleeve is firmly in contact with the 1/16" offset of the Bolt Setter's bolt bushing. Place assembly into clean undercut hole with the setting ring between the bottom of the bolt setter and the concrete surface. Grasp Hand Bolt Setter handle and turn hex nut in a clockwise direction. using a box end wrench or adjustable wrench. When pin is within 3/16" of the top of slot and the torque required to turn the Hand Bolt Setter hex nut has increased considerably, the anchor is set. Loosen hex nut. Remove Hand Bolt Setter by rotating it in a counterclockwise direction. See Figure 5 and Figure 6.

3.3.3.2 Unscrew stud extender from anchor and remove setting sleeve from hole. If a short length of sleeve was removed from above the plastic washer, replace it now.

3.3.3.3 Insert internally threaded coupling into-hole, chamfered end first, and thread onto anchor.

3.3.4 Hydraulic Setting

3.3.4.1 Check to ensure that components required for hydraulic setting are present and assembled. See Figures 3.

3.3.4.2 Remove internally threaded coupling from anchor and thread stud extender onto the stud end of the anchor. In some cases there is a short length of sleeve above the anchor's plastic washer which must also be removed. Put setting sleeve over the stud extender. Place the end of the stud extender through the center hole of the special Bolt Bushing provided. The Bolt Bushing should be oriented so that the 1/16" offset bears against the setting sleeve. Position the Bolt Bushing in the center of the Base Plate, place Draw Bar through the center hole of the hydraulic cylinder, and attach Draw Bar to the stud extender.

3.3.4.3 Place the anchor into the drilled and undercut hole so that the Base Plate on the hydraulic cylinder is in contact with the surface of the concrete or attachment. Load the bolt to the values specified in Table III. Remove the Draw Bar, Hydraulic Cylinder and Bolt Bushing from the anchor.

3.3.4.4 Unscrew stud extender from anchor and remove setting sleeve from hole. If a short length of sleeve was removed from above the plastic washer, replace it now.

3.3.4.5 Insert internally threaded coupling into hole, chamfered end first, and thread onto anchor.

3.4 Tensioning Anchor

3.4.1 Torque Tensioning

3.4.1.1 Torque anchors to values specified in Table III. It is suggested that a click or breakaway type torque wrench be employed to insure that the maximum torque is not excedded.

3.4.2 Hydraulic Tensioning

3.4.2.1 Screw threaded rod into coupler with a thread engagement of at least on stud diameter. Replace and finger tighten nut and washer on anchor stud bolt. Place a center pull hydraulic cylinder over the anchor stud and bridge cylinder so that it leaves the hex nut exposed and bears on the concrete surface or attachment around the anchor. Turn the draw bar down onto the anchor and tension it to the values specified in Table III. (Table III gives values for A193 Grade B7 material. For other materials see the Tables for Other Materials.) Tighten down the hex nut to retain the load. Release the pressure and remove the hydraulic cylinder. See Figure 3.

For Setting and Tensioning Loads with Data for Drillco Supplied RC-Series Cylinders see Table III (RC Data)

For Setting and Tensioning Loads with Data for Drillco Supplied RCH-Series Cylinders see Table III (RCH Data)