Code Requirements for Nuclear Safety Related Concrete Structures (ACI 349-97) and Commentary-ACI 349R-97

Reported by ACI Committee 349

American Concrete Institute

P.O. BOX 9094

FARMINGTON HILLS, MICHIGAN 48333

APPENDIX B-Steel Embedments

B.0 - Notation

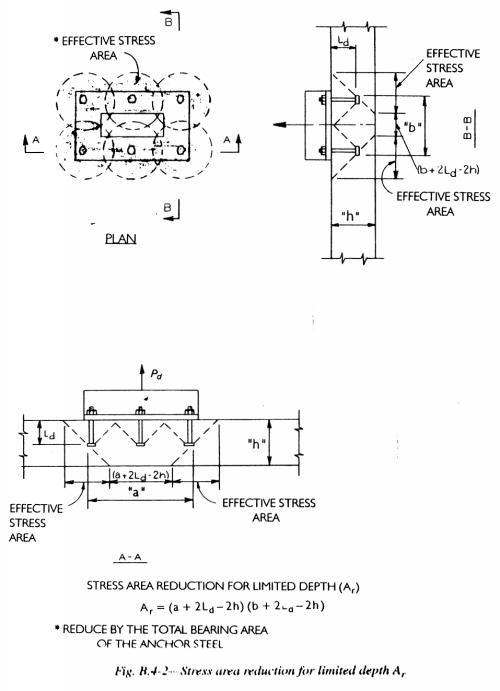

a = length of an anchor group, measured out to out of bearing edges of the outermost anchor heads (see Fig. B.4-2), in.

Ab = bearing area of shear lug, sq. in.

Ae = the tensile stress area for threaded anchors, the gross area for anchors without threads, the lesser of the gross area or the tensile stress area for anchors with upset threads, in.2. The tensile stress area of a threaded anchor shall be taken as:

0.7845 [D - (0.9743/n)]2

Ar = reduction in effective stress area to account for limited depth of concrete beyond the bearing surface of the embedment (see Fig. B.4-2), sq. in.

b = width of an anchor group, measured out to out of bearing edges of the outermost anchor heads (see Fig. B.4-2), in.

C = the compressive resultant force between the embedment and the concrete from factored moment and factored axial load applied to the embedment (see B.6.5.2.1), lb.

D = basic major diameter of threaded part, in.

fb = bearing strength for shear lug, psi

f'c= specified compressive strength of concrete, psi

fut= specified ultimate tensile strength of steel, psi

fy = specified yield strength of steel, psi

h = overall thickness of concrete member containing embedment or height of shear lug, in.

Kc = confinement coefficient (see B.5.1.2.2)

Ld = embedment depth of anchor head measured from attachment of anchor head to tensile stress component, to the concrete surface, in.

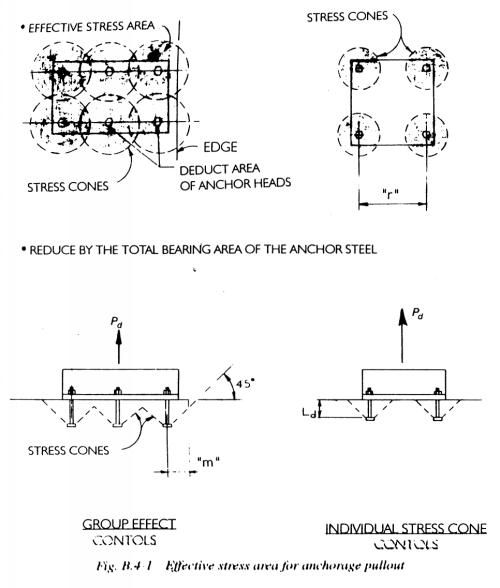

m = minimum edge distance from the center of the tensile stress component or anchor head to the edge of the concrete (see Fig. B.4-1), in.

n = number of threads per in.

Pa = factored external axial load on the anchorage (see B.5.1.2.2), lb

Pd = design pullout strength of concrete in tension, lb

Py = tension strength of the tension anchors (see B.5.1.2.2), lb

s = clear distance face-to-face between shear lugs, in.

U = required strength, to resist factored loads or related internal moments and forces  = strength reduction factor, dimensionless

= strength reduction factor, dimensionless

B.1-Scope

B.1.1 This appendix provides minimum requirements for design and anchorage of steel embedments used to transmit loads from attachments into reinforced concrete structures by means of tension, bearing, shear, friction, or any combination permitted by this appendix.

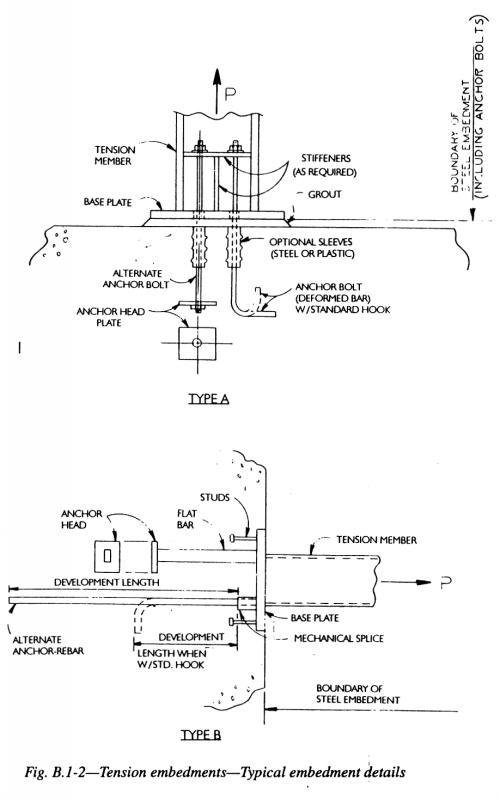

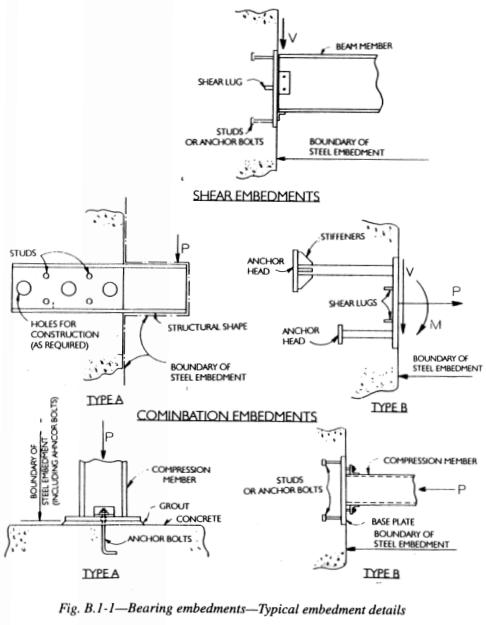

Typical embedment details and concepts as referenced in this appendix are shown in Fig. B.1-1 and B.1-2. In addition to meeting these requirements consideration shall be given to the effect of the forces applied to the embedment on the behavior of the overall structure.

B.1.2 The requirements for the attachment to the embedment shall be in accordance with applicable codes and are beyond the scope of this appendix.

B.1.3 Design limits less conservative than those specified in this appendix may be used by the Engineer if substantiated by experimental or detailed analytical investigation.

B.2-Definitions

Anchor-Steel component used to transmit loads from the attachment into the concrete. Anchors include, but are not limited to, bolts, welded studs, threaded rods, bars, undercut anchors, and expansion anchors.

Anchorage-The process of attaching a member or object to the concrete structure by means of an embedment, taking into consideration those factors (e.g., depth of embedment, edge distance, and spacing of anchors) which determine the load capacity of the anchorage system.

Anchor head-A nut, flat washer, plate, stud, or bolt head used to transmit loads from the tensile strength component to the concrete by bearing.

Attachment-The attachment is that structure external to the surfaces of the embedment which transmits loads to the embedment.

Embedment-The embedment is that steel component embedded in the concrete used to transmit applied loads to the concrete structure. The embedment may be fabricated of plates, shapes, bolts, reinforcing bars, shear connectors, expansion anchors, inserts, or any combination thereof.

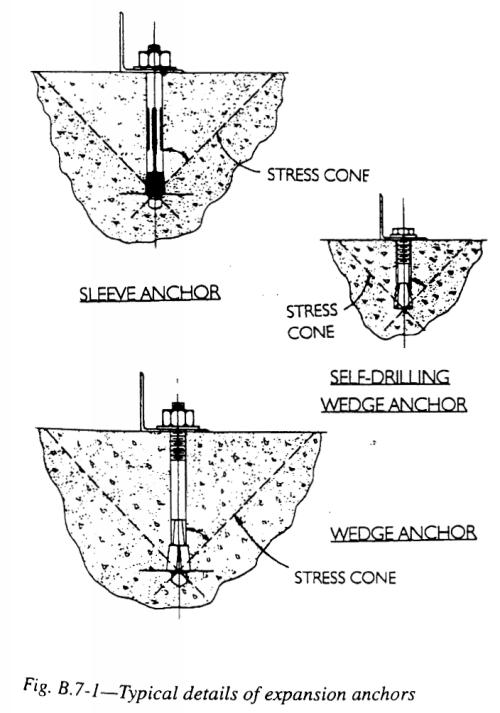

Expansion anchor-Component that is installed in a hole drilled in hardened concrete and then is expanded in order to transfer loads into the concrete by direct bearing and/or friction.

Expansion mechanism-A mechanism used to transmit load from the tensile stress component to the concrete when used as part of an expansion anchor.

Grouted Embedments-An embedment located in a formed or drilled hole in hardened concrete utilizing a grout to provide load transfer from the embedment to the concrete.

Inserts--Commercially available, predesigned, and prefabricated embedments installed prior to concrete placement which are specifically designed for attachment of bolted connections.

Strength, design-Nominal strength multiplied by a strength reduction factor  .

.

Strength, nominal-Strength of a connection calculated in accordance with the provisions and assumptions of the strength design method of this code before application of any strength reduction factors.

Tensile stress component-That part of the embedment attached to the anchor head or expansion mechanism used to transmit tensile loads to the concrete.

B.3-General requirements and loading combinations

B.3.1 The embedment and surrounding concrete or grout shall be designed for transmitting to the concrete structure all loads used in the design of the attachment. Assumptions used in distributing loads within the embedment shall be consistent with those used in the design of the attachment.

B.3.2 Reactions on the embedment due to individual loads such as dead, live (including vibratory loads), thermal, seismic, and accident loads shall be considered. The loading combinations for embedment design shall be in accordance with 9.2 of this code.

B.3.3 Material and testing requirements for embedment steel shall be specified by the Engineer to ensure that the embedment design is compatible with the intended function of the attachment.

B.3.4 The design strength of embedment materials may be increased in accordance with Appendix C for embedments subject to impactive and impulsive loads.

B.3.5 The strength of embedments as affected by the size and grade of steel, spacing, and depth of embedment and any concrete dimensions which limit or restrict the transfer of loads from steel to concrete shall be considered as defined in B.4, B.5, and B.6.

B.3.6 Plastic deformation of the embedment is permitted for impactive and impulsive loading provided the strength of the embedment is controlled by the strength of the embedment steel as specified in B.5. For these conditions a maximum ductility ratio of 3 may be considered. The definition of ductility ratio shall be as defined in Appendix C.

B.3.7 A combination of bearing and shear friction mechanisms shall not be used to develop the design shear strength defined in accordance with 9.3 of this code. The available confining force afforded by the tension anchors in combination with external loads can, however, be utilized in determining the shear capacity of anchorages with shear lugs.

B.4-Design requirements for concrete

B.4.1 The design provisions of this appendix are based on the strength design method. The assumptions, principles, and requirements of the code are applicable for all load combinations except as modified herein.

B.4.2-Tension

The design pullout strength of concrete Pd for any embedment shall be based on a uniform tensile stress of  acting on an effective stress area which is defined by the projected area of stress cones radiating toward the attachment from the bearing edge of the anchor heads. The effective area shall be limited by overlapping stress cones, by the intersection of the cones with concrete surfaces, by the bearing area of anchor heads, and by the overall thickness of the concrete (see Fig. B.4-1 and B.4-2). The inclination angle for calculating the projected area shall be 45 deg.

acting on an effective stress area which is defined by the projected area of stress cones radiating toward the attachment from the bearing edge of the anchor heads. The effective area shall be limited by overlapping stress cones, by the intersection of the cones with concrete surfaces, by the bearing area of anchor heads, and by the overall thickness of the concrete (see Fig. B.4-1 and B.4-2). The inclination angle for calculating the projected area shall be 45 deg.

The strength reduction factor  shall be as follows:

shall be as follows:

a) Embedments anchored beyond the member far face reinforcement . . . . . . . .0.85

b) Embedments anchored in a compression zone of a member . . . . . . . . . . . . . . . .0.85

c) Embedments anchored in a tension zone of a member where the concrete tension stress (based on an uncracked section) at the concrete surface is less thanfor the load combinations and load factors defined in 9.2 . . . . . . . . . . .0.85

d) All other embedments . . . . . . . . . . . . . . 0.65

B.4.3-Shear

The design shear strength of embedments subject to shear shall satisfy the requirements of B.5.1.2 and B.6.2.2.

B.4.4-Reinforcement

If the requirements of B.5 are not satisfied, reinforcement shall be provided to develop the required strength. Reinforcement requirements shall be in accordance with applicable sections of this code and placed to prevent failure of the concrete in tension.

B.4.5-Bearing

B.4.5.1 The bearing requirements of 10.15 or 18.13 of this Code shall apply to the average bearing stress at an anchor head except as permitted in B.4.5.2.

The design bearing strength used for concrete or grout placed against shear lugs shall not exceed  (1.3f 'cAb) using a strength reduction factor

(1.3f 'cAb) using a strength reduction factor  of 0.70. For grouted installations, the value f'c, shall be the compressive strength of the grout or the concrete whichever is less.

of 0.70. For grouted installations, the value f'c, shall be the compressive strength of the grout or the concrete whichever is less.

B.4.5.2 For bolts meeting the requirements of ASTM Specifications A 307, A 325, or A 490 or if the anchor head at the base of the tensile stress component satisfies the following conditions: (a) The bearing area of the anchor head including the area of the tensile stress component is at least 2.5 times the area of the tensile stress component. (b) The thickness of the anchor head is at least 1.0 times the greatest dimension from the outer most bearing edge of the anchor head to the face of the tensile stress component. (c) The bearing area of the anchor head is approximately evenly distributed around the perimeter of the tensile stress component.

B.5-Anchorage requirements

B.5.1 Anchorage design shall be controlled by the strength of embedment steel unless otherwise specified in this appendix.

B.5.1.1-Tension

Steel strength controls when the design pullout strength of the concrete Pd as determined in B.4.2 exceeds the minimum specified tensile strength of the tensile stress component (based on fut) of the embedment steel, and full load transfer is accomplished from steel to concrete within the depth of the anchorage by one of the following methods:

a) An anchor head at the base of the tensile stress components which satisfies the requirements of Section B.4.5.2. To prevent failure due to lateral bursting forces at anchor heads, the minimum side cover distance m shall be determined such that the lateral concrete design strength (based on a uniform tensile stress of  acting on an effective area, including overlapping stress cones, defined by projecting a 45 deg cone from the anchor head to the free surface) exceeds the lateral bursting force unless the requirements of B.4.4 are met. The

acting on an effective area, including overlapping stress cones, defined by projecting a 45 deg cone from the anchor head to the free surface) exceeds the lateral bursting force unless the requirements of B.4.4 are met. The  factor shall be taken as 0.85.

factor shall be taken as 0.85.

b) Reinforcing bars with development lengths in accordance with the requirements of Chapter 12, for anchor steel composed of reinforcement.

B.5.1.2--Shear

B.5.1.2.1-Bolts, studs, or bars

Bolts, studs, or bars shall meet the requirements of B.5. 1. 1. The minimum edge distance m for shear loading toward a free edge shall be such that the concrete design strength (based on a uniform tensile stress of  acting on an effective area defined by projecting a 45 deg half-cone to the free surface from the centerline of the tensile stress component at the shearing place) exceeds the ultimate shear strength of the bolts, studs, or bars (based on fut).

acting on an effective area defined by projecting a 45 deg half-cone to the free surface from the centerline of the tensile stress component at the shearing place) exceeds the ultimate shear strength of the bolts, studs, or bars (based on fut).

B.5.1.2.2-Shear lugs

The shear strength of grouted or cast-in-place anchorages with shear lugs shall include consideration of the bearing strength of the concrete or grout placed against the shear lugs, the shear strength of the concrete or grout placed between shear lugs and the confinement afforded by the tension anchors in combination with external loads. Shear loads toward free edges and displacement compatibility between shear lugs shall be considered.

a) When multiple shear lugs are used to establish the design shear strength in a given direction, the magnitude of the allotted shear to each lug shall be in direct proportion to the total shear, the number of lugs, and the shear stiffness of each lug.

b) For shear lugs bearing in the direction of a free edge, the design shear strength for each lug shall be determined based on a uniform tensile stress of  acting on an effective stress area defined by projecting a 45 deg plane from the bearing edges of the shear lug to the free surface unless the requirements of B.4.4 are met. Bearing area of the shear lug shall be excluded from the projected area. The

acting on an effective stress area defined by projecting a 45 deg plane from the bearing edges of the shear lug to the free surface unless the requirements of B.4.4 are met. Bearing area of the shear lug shall be excluded from the projected area. The  factor shall be taken as 0.85.

factor shall be taken as 0.85.

B.5.1.3 For combined tension and shear, the depth of embedment shall be in accordance with B.5.1.1 and the minimum edge distance in accordance with B.5.1.2.1.

B.5.1.4 Where reinforcement is provided in accordance with B.4.4, the minimum edge distance shall not be less than one-third that required by B.5.1.2. The reinforcement shall also satisfy the concrete cover requirements in 7.7 of this code.

B.6-Design requirements for embedment steel

B.6.1 Design strength provided by the embedment steel in terms of flexure, axial load, shear, and torsion, shall be taken as the nominal strength calculated in accordance with the requirements and assumptions of this section, multiplied by a strength reduction factor  .

.

B.6.2 strength reduction factor  shall be as follows:

shall be as follows:

B.6.2.1 Flexure and/or axial load . . . . . 0.90

B.6.2.2 Shear and torsion . . . . . . . . . . . . 0.85

B.6.3 Embedment materials other than reinforcing bars shall have a minimum elongation of 14 percent in 2 inches when tested in accordance with ASTM A 370.

Embedment materials without a distinct yield point shall be permitted. For such materials the yield strength fy shall be defined as the 0.2 percent strain offset method in ASTM A370.

B.6.4 Anchors that incorporate a reduced section in the load path shall satisfy one of the following conditions:

a) The ultimate tensile strength of the reduced section shall be greater than the yield strength of the unreduced section.

b) For bolts, the length of thread in the load path shall be at least two anchor diameters.

B.6.5-Anchors

Anchors shall be designed for tension and shear loads in accordance with B.6.5.1, B.6.5.2 and B.6.5.3.

B.6.5.1-Tension

The nominal tensile strength of an anchor shall be fyAe

B.6.5.2-Shear

The nominal shear strength attributed to anchors shall be determined by B.6.5.2.1 or B.6.5.2.2, whichever is applicable.

B.6.5.2.1 For connections with the contact surface of the baseplate flush with the surface of the concrete, the nominal shear strength of an anchor shall be . . . . . 0.70fyAe

For built-up grout pads, the nominal shear strength shall be multiplied by . . . . . 0.80

Friction between the baseplate and concrete may be considered to contribute to the nominal shear strength of the connection. The nominal shear strength resulting from friction between the baseplate and concrete (i.e., without any contribution from anchors) may be taken as 0.40C

B.6.5.2.2 For connections with the contact surface of the baseplate below the surface of the concrete, the shearfriction provisions of 11.7 of this code (as modified by this section) shall be used. The shear-friction coefficient shall be as follows:

Baseplates without shear lugs . . . . . . . 0.9

Baseplates with shear lugs which are designed to remain elastic . . . . . 1.4

B.6.5.3-Combined tension and shear

B.6.5.3.1 The interaction of tension and shear for anchors designed in accordance with B.6.5.1 and B.6.5.2.1 (shear transfer by anchor bearing) shall be assumed to be linear (additive) or elliptical.

B.6.5.3.2 For anchors designed in accordance with B.6.5.1 and B.6.5.2.2 (shear transfer by shear-friction), the area required for tension due to applied load and the area required for tension due to shear-friction shall be additive.

B.6.6-Structural shapes, fabricated shapes, and shear lugs

The design strength of embedded structural shapes, fabricated shapes, and shear lugs shall be determined using a steel stress of  fy, where

fy, where  shall be taken as 0.9 for tension, compression and bending, and 0.55 for shear.

shall be taken as 0.9 for tension, compression and bending, and 0.55 for shear.

B.7-Expansion anchors

This section provides minimum requirements for the design of typical expansion anchors used in concrete structures and does not restrict the use of other expansion anchors provided the expansion anchors are designed and tested in accordance with the requirements of this section.

B.7.1-Design requirements

Expansion anchors shall be designed to assure that the design strength of concrete for a given expansion anchor or group of expansion anchors is greater than the strength of the anchor steel except as permitted in B.7.2. The requirement shall be met by satisfying the requirements of B.7.1.1 or B.7.1.2.

B.7.1.1-Design by analysis

a) Tension: The design pullout strength of concrete Pd shall be as defined in B.4.2 except that the effective stress area shall be defined by the projected area of the stress cone radiating toward the concrete surface from the innermost expansion contact surface between the expansion anchor and the drilled hole. Refer to Fig. B.7-1 for typical details. The design pullout strength of concrete shall be equal to or greater than the minimum specified tensile strength or average tensile strength if a minimum is not defined for the expansion anchor. The minimum edge distance shall be in accordance with the requirement of B.5.1.1(a).

b) Shear: Expansion anchors subject to shear shall meet the requirements of B.5.1.2.1.

c) For combined tension and shear, the depth of embedment shall be in accordance with B.7.1.1(a) and the minimum edge distance in accordance with B.7.1.1(b).

d) The design requirements for embedment steel shall be in accordance with B.6.0.

B.7.1.2-Design by testing

Tests shall be conducted to verify that the concrete will develop the steel strength of the expansion anchor. Design by test results shall be restricted to tests that are representative of the anchor spacing and load application.

B.7.1.3-Strength reduction factors

The requirements of B.6 shall apply except that the  factors for expansion anchors shall be 0.9 times the values specified in B.6.2.

factors for expansion anchors shall be 0.9 times the values specified in B.6.2.

B.7.2-Alternative design requirements

For expansion anchors that do not meet the requirement of B.7. 1, the design strength shall be 0.33 times the average tension and shear test failure loads. The average test failure load shall be equal to the average of the test loads carried by test anchors at failure (maximum load) or at a magnitude of displacement of test anchors as specified by the Engineer.

B.7.3 A single expansion anchor used to anchor an attachment shall be designed for one-half of the design strength defined herein.

B.7.4-Testing

B.7.4.1 Expansion anchors designed in accordance with B.7.1.1 or B.7.1.2 shall be tested to verify the ability of the expansion mechanism to develop the tensile strength of the tensile stress component. Expansion anchors designed in accordance with B.7.2 shall be tested to determine the average test failure load. Tests shall be conducted by a testing agency other than the expansion anchor manufacturer and shall be certified by a professional Engineer with full description and details of the testing program, procedures, results, and conclusions.

B.7.4.2 The expansion mechanism of the expansion anchor shall be tested for the installed condition by one of the following methods:

a) The mechanism shall be actuated and tested during installation by preloading the expansion anchor to a minimum value as specified by the Engineer.

b) A random selection of the installed expansion anchors shall be load tested to a minimum of 100 percent of the design strength. The testing program shall be established by the Engineer.

B.7.5-Expansion anchor selection

The Engineer shall review the expansion anchor design features, failure modes, test results, and installation procedures prior to selecting a specific expansion anchor for an application. Expansion anchors shall not be used to resist vibratory loads unless tests are conducted to verify the adequacy of the specific expansion anchor and application. In the selection of expansion anchors, consideration shall be given to expansion anchor performance in cracked concrete.

B.8-Inserts

Concrete inserts shall be specified in accordance with B.6.1 and tested in accordance with B.7.4.1.

B.8.1-Design requirements

When inserts cannot be designed to meet the requirements of B.4, B.5, and B.6, the design strength shall be based on actual test data of tests performed on inserts embedded in concrete. The tests shall cover the full range of possible loading conditions.

B.8.2-Strength reduction factor

When inserts cannot be designed to meet the requirements of B.4, B.5, and B.6, a  factor of 0.5 shall be applied to the average test failure loads in determining design strength.

factor of 0.5 shall be applied to the average test failure loads in determining design strength.

B.9-Grouted embedments

B.9.1 Grouted embedments shall meet the applicable requirements of B.4, B.5 and B.6.

B.9.2 For general grouting purposes the material requirements for cement grout shall be in accordance with Chapter 3 of this code. Special grouts used to achieve certain properties such as high strength, low shrinkage, or expansion shall be the responsibility of the Engineer and specified in contract documents.

B.9.3 Grouted embedments shall be tested to verify anchorage strength. Grouted embedments installed in tension zones of concrete members shall be capable of sustaining design strength in cracked concrete. Tests shall be conducted by an independent testing agency and shall be certified by a professional Engineer with full description and details of the testing programs, procedures, results, and conclusions.

B.9.4 Grouted embedments shall be tested for the installed condition by testing randomly selected grouted embedments to a minimum of 100 percent of the required strength. The testing program shall be established by the Engineer.

B.9.5 The tests required by B.9.3 and B.9.4 may be waived by the Engineer if tests and installation data are available to insure that the grouted embedment will function as designed or if the load transfer through the grout is by direct bearing or compression.

B.10-Fabrication and installation

Welding of attachments to large embedments shall be in accordance with good practice to avoid excessive expansion of the embedment which could result in detrimental spalling or cracking of the concrete or excessive stress in the embedment.